Following the successful transportation and landing of the Booster Compression Module (BCM) on the Ichthys Explorer CPF earlier in the year, work continues on the facility as the Phase 2b project progresses.

We caught up with Wang Wei Lau, our Phase 2b Lead, to find out more about the project.

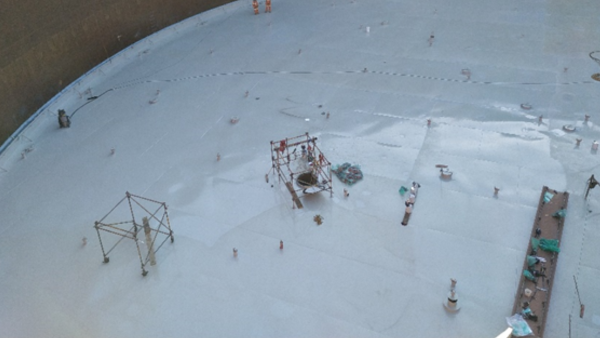

Booster Compression Module Transport, lift and installation

After over two years at the fabrication yard in Batam, Indonesia, construction of the BCM was completed, and the module was prepared for transport.

The module was transported to the Ichthys Field by Heerema’s heavy lift vessel Sleipnir. Sleipnir is the world’s largest semi-submersible crane vessel; a 220 x 102 metre vessel with twin cranes capable of lifting 10,000 metric tonnes each.

The BCM measures 30m x 30m x 25m and weighs around 4,800 tonnes; and upon arrival to the field, it was lifted onto the facility with one of Sleipnir cranes and a 322-tonne spreader beam. This highly rehearsed manoeuvre only had 10 centimetres clearance on either side and is the largest single crane lift between semi-submersible facilities in open water.

Phase 2b: Extending production

The introduction of the BCM onto the facility will enable our customer to extend production plateau and improve gas recovery. In short, it allows for extended of the field life and greater efficiency.

“There are still many hurdles and challenges to come before we complete the project,” Wang Wei shared.

“But we’re confident that the leadership team and crew we have onboard will be up for it.”

Next steps

After the module transport and installation, focus has now turned towards plugging the module in and getting it ready for operation. Key activities that the Monadelphous team have been involved in includes:

- Welding down the BCM legs.

- Safely removing the guides installed to protect the BCM and CPF during the module installation and install permanent access ways.

- Preparing for the offshore shutdown in the coming months by making sure the necessary electrical and instrumentation infrastructure is in place (over 60km of electrical and instrument cables to be pulled and terminated).

- Integrating the new heat exchanger and seawater lift pump into the existing CPF seawater system and more.

Leave a comment