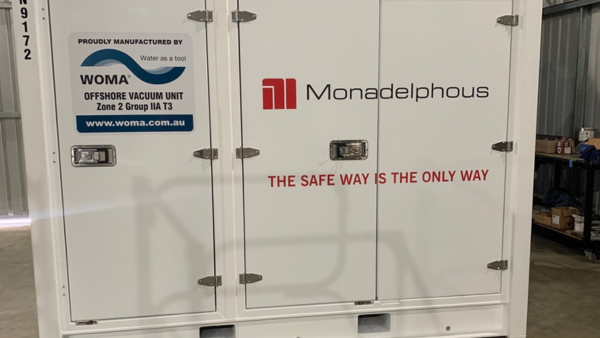

This just in…our eighth Ultra High Pressure (UHP) pump has arrived!

Last week, our Industrial Services team visited manufacturer WOMA Australia for a final inspection of our new pump, prior to it commencing its journey to a customer offshore facility.

We use ultra high pressure pumps across our offshore operations for removal of degraded paint and any other impurities in surface preparation for repainting.

This project involves remediation of a structure that has been in service for several decades and is due for a major recoating campaign.

M&IS Energy Project Director, Peter Davis, said our continued growth in the fabric maintenance space is a major success story for our business.

“Over the past few years, we have strategically invested in state-of-the-art equipment and technologies to strengthen our service offering and better support our customers and the maintenance of their assets,” he said.

Peter shared that historically we had been reliant on subcontractors for UHP works who provided their own equipment, which came with its challenges.

“By using our own modern equipment, such as UHP pumps, there are significant benefits for us and our customers, not only for cost effectiveness, but also for operational efficiency, enhanced safety, as well as the reliability of the pumps when compared to externally sourced equipment,” he said.

Leave a comment