Looking for ways to innovate our everyday operations is something that can help make our jobs easier, safer and more efficient – every idea, whether it’s big or small, is welcome in our business.

We encourage you to share your ideas via MProve, by emailing our innovation team innovation@monadel.com.au or by speaking to your supervisor.

Check out some of our team’s recent submissions for inspiration! Well done to everyone who submitted an idea and for thinking outside of the box.

The Claw

Idea posted by the Shovel 344 Shutdown team from M&IS Eastern Region

It was identified that the handling of large circular components from mechanical assemblies without designated lifting points posed a hazard to workers during removal and installation. "The Claw" is a fit for purpose tool designed to remove workers hands from the line of fire.

The concept behind the design was loosely based on coupling pullers. The 3 arms of the claw can be contracted or expanded by turning the upper wing nut. The design allows for interchangeable customised feet to be installed to the ends of the legs for different scenarios, including lifting from the inside and outside.

BENEFITS

Health, Safety & Environment: Reduced worker's hands being in the line of fire when utilised compared to the traditional methods; stable lifting device for round objects without lifting points.

Productivity: Less personnel were required to be involved in the task as the rigging was simplified, meaning heavy loads don't need to be handled with multi-person lifts.

Quality: Removed requirement to weld temporary attachments to machined items for lifting and handling.

Current Status: The Claw has been used on the Shovel 344 Shutdown for lifts involving the centre gudgeon upper nut (930kg), thrust washer (200kg), and spherical washer (261kg). It is expected that The Claw will have multiple uses around NSW Operations and other sites doing similar work.

C-Hook Lifting Frame

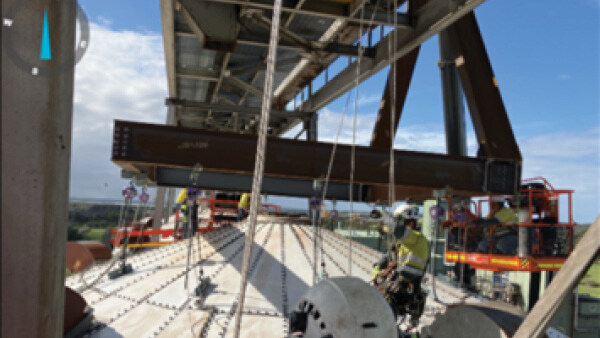

Idea posted by Jake Ayliffe (Site Manager) on behalf of the Cargill Silo Roof Replacement team from M&IS Eastern Region

A client reached out to the Newcastle team with a failing roof structure on 3 grain silos ~30m in height that were also covered by a gantry, making crane space a challenge. Initially the client explored traditional solutions, such as scaffolding the silos and constructing roof structures from scratch or potentially removing the gantry altogether.

The lifting methodology developed by our team was for the removal of the structures, harnessing mechanical teams, rope access, critical lifts, and detailed engineering of a custom-designed lifting beam.

BENEFITS

Health, Safety & Environment: - The custom lifting beam was the key to the success of the plan. Several designs were developed, with the C-hook design being preferred to provide the required manoeuverability and strength.

Current Status: The innovative lifting approach developed by the Monadelphous team successfully removed the silo roof structures, maximising productivity for the client while maintaining strict adherence to HSE standards.

Leave a comment